Our Instrumentation and Application Services

AneCom AeroTest provides various instrumentation and application services. We select and define suitable instrumentation and measurement methods in accordance with our customer’s requirements. In order to apply the instrumentation, we use standardised application methods or develop customised methods as specified by our clients, in collaboration with our experienced in-house instrumentation design and analysis team.

What is Instrumentation and Application?

Our services include reworking of mechanical parts, such as drilling, milling, electronic discharge machining (EDM), sanding, etc. in accordance with the manufacturing blueprints to prepare for the application of the instrumentation.

This is done in-house or with one of our certified suppliers.

We prepare and clean the parts prior to the application of the specified instrumentation by means of sand blasting, ultrasonic cleaning, grit blasting, degreasing, etching, etc.

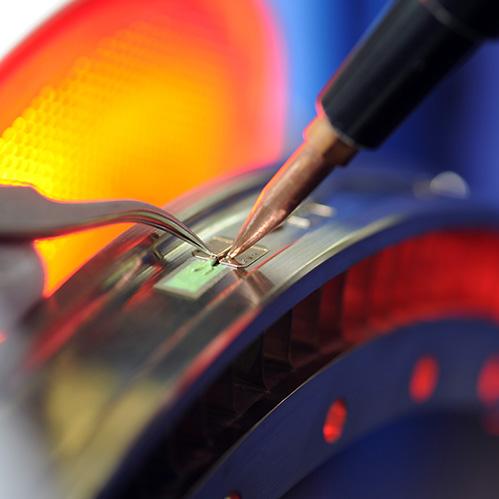

After modification of the parts we apply the instrumentation by means of brazing or soldering, vacuum brazing, welding, spot welding, flame spray or various adhesives and ceramic bonding materials.

Types of Instrumentation

- strain gauges with temperatures ranging from 0° C to 1.250° C

- pressure and temperature probes

- thermal crystals

- static and dynamic pressure tapping points and transducers

- accelerometers

- tip timing, clearance and displacement probes

- telemetry systems

- slip ring units

- traverse equipment

Quality check

We route and clip lead-out cables and tubes by bonding or spot-welding them with shim clips. We also manufacture three- and five-hole pitot static (pressure) probes and rakes fitted with temperature and/or pressure sensors.

We utilise our in-house facility to calibrate the rakes and probes with a flow rate of up to Mach 1.

Once the instrumentation has been installed, we carry out functional checks, and the quality of work is approved and documented by means of a certificate of conformity. Assembly of modules is carried out in-house (i.e. full test vehicle assembly).

Alternatively, we also pack and send single parts out to end customers. Visual inspections of existing instrumentation are carried out and if damage is detected, this is reported and repaired as necessary.

Functional tests are carried out and documented.

Your Partner for Instrumentation

With more than 15 years’ experience in instrumentation and application projects we are able to provide a hugh range of instrumentation types with a high quality standard.

Thanks to our rigorous approach to our work, AneCom AeroTest is your ideal partner for instrumentation and testing of turbine machinery components.

Your Benefits

- over 15 years’ experience in instrumentation and application projects

- various application methods adaptable to your needs

- in-house instrumentation laboratory

- integrated planning and logistics for smooth operation

- close connection to in-house design and analysis department