Combustor Test

What is a combustor test?

- Test combustor component for aircraft engines or industrial gas turbines as part of a development programme

- Establish complete combustor operating characteristics, including exploration of operating limits

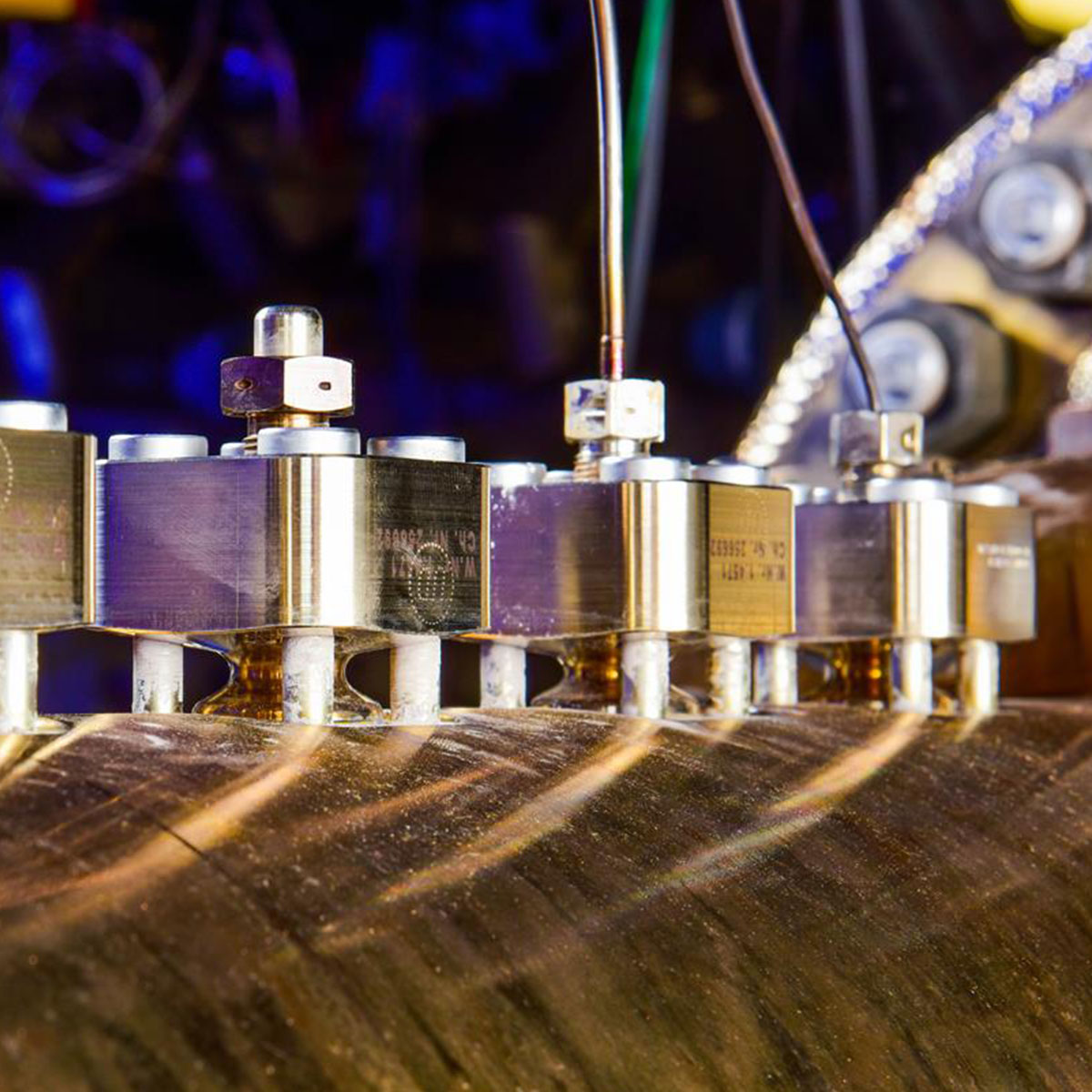

- Functional tests of fuel nozzles

- Measure & optimise emission level (NOX, CO2)

- Ignition and extinguishing testing, including altitude relight testing for aero-engines

- Investigate aero-acoustic phenomena (combustor “rumble”)

- Combustor operation with different fuels (industrial & power plant gas turbines)

- Provide data base for improvement of the numerical algorithms

Keyfacts

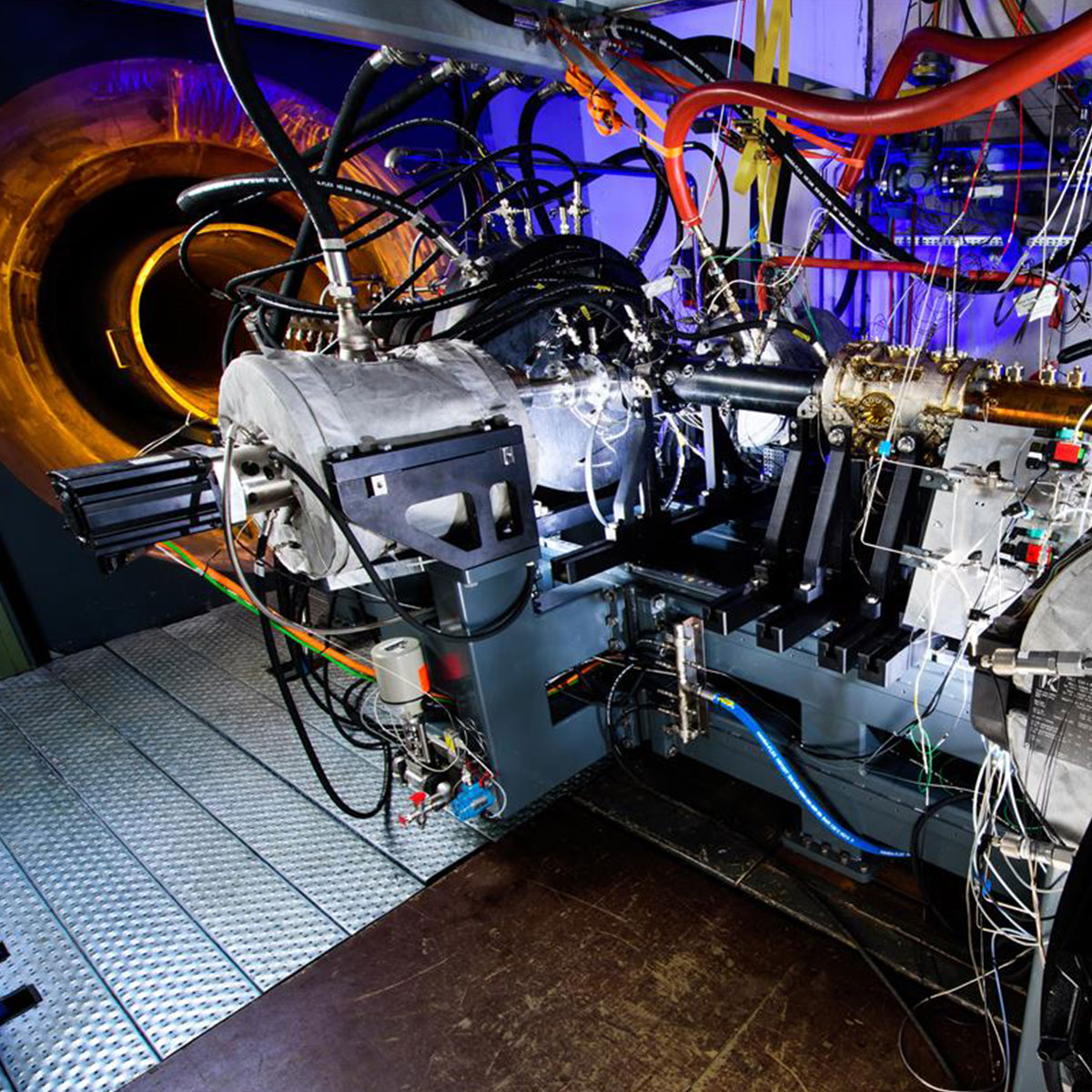

Combustor tests are carried out at external test facilities with certified partner organisations or at the customer site.

We have gathered special experience at the test facilities of the German Aerospace Centre (DLR) in Cologne where more than 100 tests have been carried out at various test facilities (HBK2, HBK3 and HBK5). Basic technical data from the Institute of Propulsion Technology at the DLR are:

- Emission test, rumble test and optical exhaust gas measurement

- EDS: optical admission, main air supply max. 1 kg/s, max. 20 bar, max 850 K

- HBK1: main air supply - max. 2.2 kg/s, max. 20 bar, max.900 K

- HBK2: main air supply - max. 30 kg/s, max. 40 bar, max. 920 K

- HBK3: main air supply - max. 7 kg/s, max. 40 bar, max. 920 K

- HBK4: main air supply - max. 45 kg/s, max. 40 bar, max. 920 K

Further details are available on German Aerospace Centre (DLR).

In addition we have used the altitude test facility of the University of Stuttgart, the Institute of Aircraft Propulsion Systems (ILA). The focus here is on ignition and extinguishing tests:

- Air supply for flow rates up to 140 kg/s

- Air condition can be adjusted between 60 °C and +170 °C at an inlet pressure of 0.05 to 2.5 bar

We will be pleased to support you in searching for, selecting and carrying out of combustor tests at other external test facilities suitable for your test needs.

We will be pleased to support you in searching for, selecting and carrying out of combustor tests at other external test facilities.