Compressor Test

What is a compressor test?

- Test compressor component for aircraft engines or industrial gas turbines as part of a development programme

- Establish complete compressor map and operating characteristics of a compressor, including determination of the operating limits (surge line, choke line)

- High resolution measurement technology used to identify stage-by-stage performance

- Provide first data in a development programme for mechanical integrity of compressor blading

- Establish and optimise bleed and VGV schedules

- Provide data base for improvement of the numerical algorithm

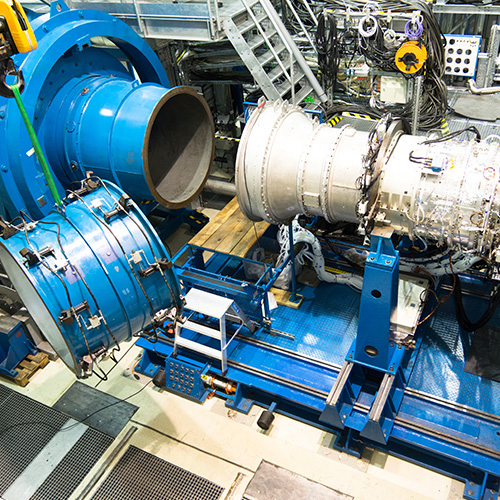

Keyfacts

- Electric drive system providing up to 18,000 kW (24,000 HP)

- 11 controllable pipe measuring sections for bleed air extraction

- Control of up to 5 (extendable to 7) variable guide vane stages driven by hydraulic jacks

- Versatile rig oil system for roller/ball or journal bearings

- Secondary air supply system, e.g. for buffer seal air or instrumentation cooling

- Versatile and programmable compressor & facility control system with built-in safety concept

- Various gear sets, speeds of up to 15,200 RPM

- Split flow test facility with maximum mass flow of 200 kg/s at the inlet, 150 kg/s at the bypass and 65 kg/s at the core

- Reduction of inlet pressure down to 0.2 bar

- Maximum compressor outlet conditions of T=460 °C and P=11.0 bar in the bypass section (or as single flow)

- Axial thrust piston to compensate maximum axial force of 80 kN

- Various gear sets, speeds of up to 24.000 RPM

- Primary single flow test facility with maximum mass flow of 50 kg/s (extension to split flow possible)

- Reduction of inlet pressure down to 0.2 bar

- Maximum compressor outlet conditions of T=640 °C and P=21.4 bar

- Inlet air can be heated up by up to 100 °C above ambient

Measurement system capabilities

- Ambient pressure, temperature and relative humidity at the facility inlet

- Pressure in the inlet Venturi

- Temperature at several points in the test facilities including the anechoic chamber

- Mass flow in the inlet Venturi/ flare (HP, IP and Anechoic), in the bleed lines (HP and IP) and in the core exhaust lines in the IP and Anechoic testbed

- Speed and torque at the drive shaft

- Compressor thrust compensation force of the balance piston (part of the torquemeter) – IP and Anechoic testbeds only

- Oil and air supply parameter for the compressor bearings

- Valve positions

- Health & safety measurements on all systems (vibrations, temperatures, pressures,etc.)

- Pressure:

- 1418 HP & IP test facility

- 1184 Noise test facility

- Temperature:

- 480 thermocouple (type E, J,K,N,T) HP & IP facility

- 300 thermocouple (type E, J,K,N,T) Noise test facility

- 32 RTD channels - Analogue voltages: >150

- Frequency inputs: 16

- Vibration channels:

- 20 HP & IP test facility

- 26 Noise test facility - DC strain: 8

- Various:

- Tip timing on Noise test facility

- Tip clearance measurement on HP & IP test facilty

- 384 channels @ 250 kHz maximum sampling rate (configurable), fully synchronized

- Used for high frequency inputs, e.g.

- vibration measurements (strain gauges)

- noise measurements

- fast pressure transducers - Real-time monitoring and limit checking of all input channels at a time

- Monitoring of up to 32 modal limits per channel

- Real-time displays, including Campbell, Z-Mod, Oscilloscopes, FFT