What are our Test Services?

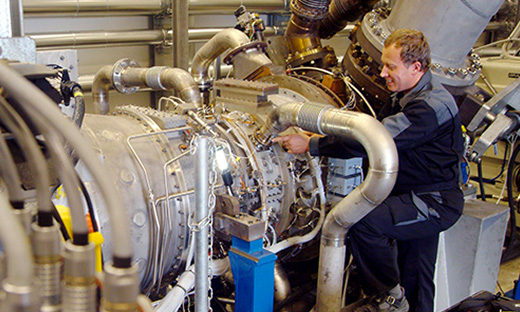

The development process for turbo machinery like aircraft engines or industrial gas turbines requires a variety of experimental tests to validate the product performance. AneCom AeroTest supports turbo machinery development OEM´s from all over the world in the aerodynamic and aero-acoustic validation of components by testing fans, compressors, combustion chambers, turbines and other flow components. To do this, we operate a state-of-the-art test centre for fans and compressors at our premises in Wildau near Berlin. In addition we collaborate with proven test facilities for combustors and turbines.

Our Experience

Since AneCom AeroTest was founded more than 15 years ago, we have conducted more than 80 fan/ compressor test campaigns and have accumulated over 8,000 test hours in our own test facility.

In addition more than 100 test campaigns for combustors and turbines have been executed. These tests are mainly carried out by AneCom AeroTest staff at certified external cooperation partners such as the German Aerospace Centre (DLR) and the Institute of Aircraft Propulsion Systems (ILA).

Using our testing services gives you access to a unique wealth of experience from a large number of customer tests with varying requirements – to the benefit of your product validation process. You will hardly find in the world a service provider with a comparable combination of our practical test experience, mature operating procedures and experienced operating personnel.

Why testing components of gas turbine?

By developing and testing individual components of a gas turbine independent from the overall engine product development, e.g. in dedicated R&D programmes, the time-to-market capabilities for a gas turbine product development is significantly reduced. Alternatively, results may also be used for an evolutionary improvement of an existing product.

Testing of gas turbine components provides a detailed understanding of component performance that cannot be obtained from full engine testing, e.g. by

- Exploring performance limits, e.g. compressor mapping including surge investigations or combustor high altitude relight capabilities

- Gaining detailed understanding of component performance, e.g. stage by stage performance in a compressor or turbine, contribution of fan component noise to the overall aero engine noise signature or temperature & emission distribution @ combustor exit

- Easier accommodation of instrumentation and measurement equipment to component test vehicles, e.g. stage-by-stage pressure and temperature instrumentation in a compressor/ turbine or temperature/ emission traversing @ combustor exit

Data from component testing are therefore also a valuable basis to validate and improve computer codes.

Cost-efficiency

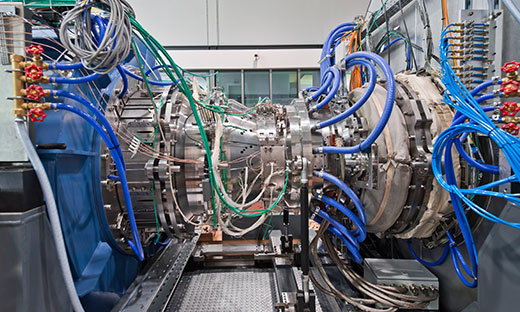

AneCom AeroTest is an independent partner for engineering and test services. As a company we have significantly invested in our state-of-the-art Compressor Test Centre which combines three different test beds in a perfect symbiosis. Additionally, as we offer compressor testing to all OEMs worldwide we achieve a well-balanced utilisation resulting in very attractive test prices for a single OEM´s test campaign. These cost benefits are supplemented by additional elements:

- The test facility is optimised for quick exchange of test units to make best use of the available test time.

- This together with a pre-configurable test operation system provides maximum flexibility to changing customer requirements.

- We invested in one test operation system to run tests on one of the three available compressor test beds. Test capacity in a given time frame may be increased by using a multishift working pattern or weekend work.

This provides our customers a cost efficient and flexible solution for professional test service.

We love testing – for you.

Can you relate a compressor test campaign to a pit stop in a Formula E race? We think you can! If you are interested in the fastest test services with highest quality output – consider the following.

Our test team consists of around forty (40) test and measurement engineers as well as mechanics, where some have already decades of professional experience in component testing.

Our Compressor Test Centre can be operated 24 hours per day including weekends without any limitation by power availability or noise emissions. We conduct tests in two-shift operation providing our customers up to 12 hours of testing on a normal working day. In addition we can arrange a 3rd shift for inspection and repair activities over night.

The reliability of test systems is essential for a smooth test operation and the quality of test data. Therefore we follow a comprehensive system-by-system maintenance schedule and replace outdated systems regulary. All measurement systems generating customer data are calibrated in defined intervals and traceable to international standards.

Over the years we have developed and optimised a reliable development test process

- which starts some 3 months before test with generating the required input for test sequence and system configuration,

- defines the daily system check routines, test monitoring and customer reporting,

- includes a change procedure to quickly react to changes in the test programme, and

- lays out the test data provision and documentation after completion of test campaign.

Comprehensive on-site test vehicle inspection, modification and repair capabilities in combination with our proven local manufacturing supply chain (link instrumentation and build) are available on a “as needed” basis.

For component tests conducted at our test partner sites, we support our customers with the full test service package similar to our inhouse testing. In addition we provide our service for test and measuring assignments on customer sites, e.g. supporting the commissioning of test facilities and measurement systems as well as full engine tests.

Welcome to the Formula E team of component testing!

Benefits

- Fastest test campaign – high quality output

- Our experience

- Highly motivated test team

- World class, reliable test facilities

- Mature operating processes

- High flexibility in adapting to specific customer test requirements

- Attractive pricing

Aerotest Services

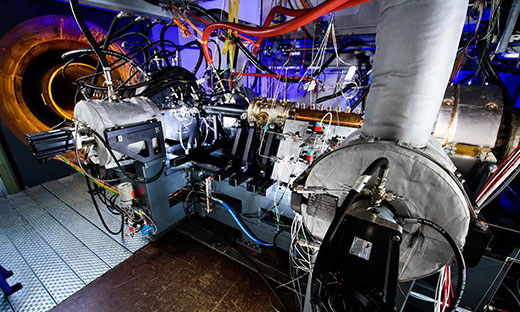

With two compressor test beds and over 15 years’ experience in this field we are your partner when it comes to testing of compressors for aero engine applications, industrial gas turbines or industrial compressors. Check out our capabilities and your benefits on our...

Compressor Test

Noise emission and fan performance are crucial parts in the aero engine development. Find out how we can support your development process with our Fan Noise and Performance Test Services.

Fan Noise and Performance Test

With the experience of over 15 years combustion testing, we are the right partner in defining test campaigns and finding the right test facility. Check out our competences in our dedicated service section.

Combustor Test

Testing test vehicles is our core competence and your advantage when working with us. An established partnership with external test facilities is evidence for this.

Turbine Test

From engine components through core engines to complete aircraft engines. We are flexible and ready to support test campaigns from Start to End.

Whole Engine Tests

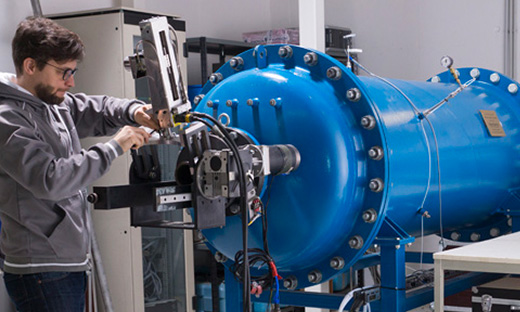

From Flow probes calibration to airflow investigations.

Find out more about our Flow Lab capabilities

Flow Lab

Traceability to standards and the quality of measurement results are key elements in our service “Flow measurement and Calibration”. Herein we investigate complex problems and offer solutions. If you are interested in more detail please follow the link below.

Flow Measurement/Calibration