Validation Strategy

AneCom AeroTest understands that the point of any campaign, rig or engine, aerothermal or mechanical, is to deliver data and that timely delivery of these data is imperative especially to support design optimisation or critical decision-making.

In addition to obtaining the data for understanding the true behaviour of a system or a component it is also necessary to demonstrate fundamental integrity and durability of the product. This applies whether certifying a new aerospace or industrial engine variant, clearing a product improvement or a necessary modification for integrity or life improvement service.

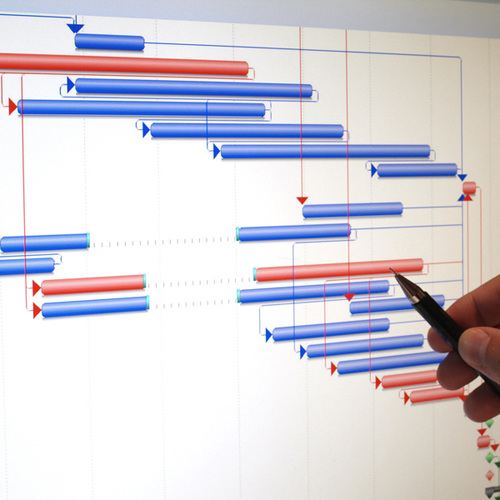

It is normal practice to create a validation strategy which, using suitably equipped test vehicles, defines the point in time when relevant data and prioritised risk reduction testing will deliver the necessary scientific data and evidence to support the engineering community within the customer organisation.

Our staff, conversant with axial and radial gas turbine designs, (large and small powerplant systems), has experience supporting Original Equipment Manufacturers OEMs, (industrial and aerospace), through integrated working consultancy agreements, in helping define Validation Strategies and Engine Development Programs (EDPs) in collaboration with our customer’s engineering teams.

This is mandatory to predict safe operation, for potential design optimisation and to correctly assess the life cycle and maintenance cycle of the product, especially if all of this is required to obtain a certified product for civil application from a relevant Certifying Authority.

Working closely with the client Program Management and the dedicated Component Engineering Teams we gather information and together, as one team, formulate an optimised and bespoke EDP that best suits the product requirements within the project and program constraints. This may include risk reduction options involving additional component or module rigs providing vital mechanical or aerothermal data. It may also require developing a supporting spares strategy to again reduce risk or optimise the time available to achieve the overall program goals.