Fan Noise and Performance Test

About Fan noise and performance test

A civil aero-engine fan is simply a single compressor stage which is the main component for generating thrust. Since the fan component is also one of the main noise sources in a civil aero-engine the test requirements are not limited to aerothermal performance. Reducing noise emissions of the fan system is an additional key development goal for civil engine applications. This goal may be achieved by improving the fan aerodynamics itself, but also by understanding and optimising the interaction of the fan with its environment. In addition noise attenuation e.g. by silencers is a valuable tool.

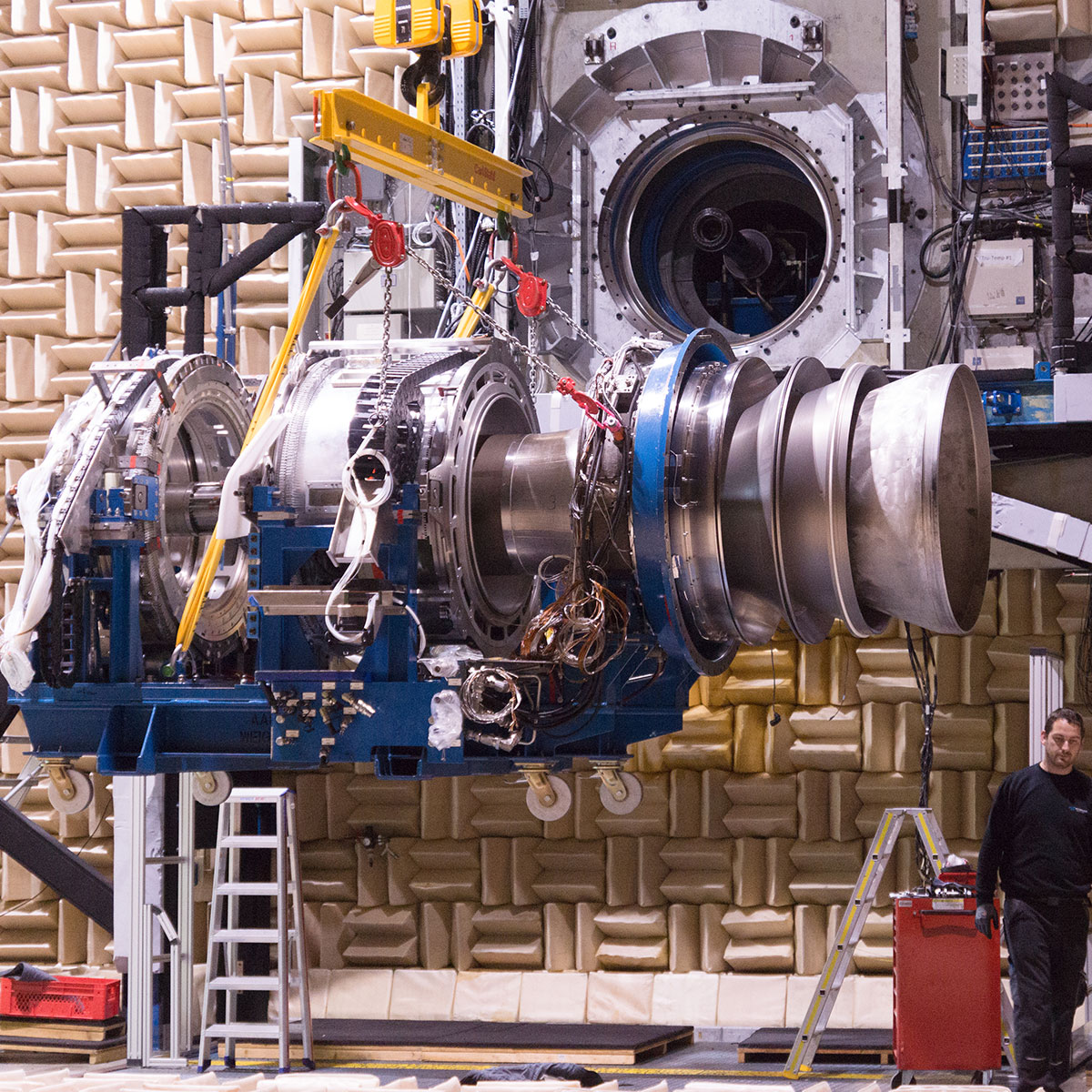

AneCom AeroTest operates Europe’s largest anechoic chamber as a powerful tool for experimental validation during fan system development. Noise reflections from test facility walls is fully suppressed in the frequency range of interest thus acoustically simulating free field conditions, e.g. like on an airfield. At the same time testing is not limited by adverse wether conditions or environmental limitations.

.

UFFA - Universal Fan Facility for Acoustic

To complement the noise test facility UFFA has been designed as a versatile and adaptable modular test vehicle to easily accommodate customer specific fan system hardware configurations in an existing test environment. Using a common hardware platform minimises the initial efforts required to design a test vehicle.

We offer the complete package from concept, design and production of the test hardware up to testing. Modularity of the UFFA test vehicle allows for quick change of multiple test configurations in the test cell speeding up a specific test campaign significantly.

The UFFA test vehicle is used for validation of hardware development (fan, OGV, liner, struts, nacelles, etc.), but also provides a realistic test case to improve calculation models (fan noise, propagation of noise in the bypass duct, noise insulation from liners, effect of noise on aerodynamics, effects of acoustic hardware on flutter).

Keyfacts

General test facility capabilities:

- Electric drive system providing up to 18,000 kW (24,000 HP)

- Primary split flow test facility, maximum mass flow 118 kg/s at the inlet, 103 kg/s at the bypass and 24.2 kg/s in the core

- Anechoic chamber footprint of 1,000 m² and 10 m height

- Noise reflection from test facility walls <1% in the frequency range 200 Hz - 40 kHz

UFFA test vehicle:

- Nominal fan diameter of 869mm (34,2’) with a maximum rotational speed of 10,000 RPM.

- Bypass ratio is largely variable, depending on the layout of the fan module as specified by the customer

- Noise emission measured in various locations upstream & downstream of fan by circumferential and axial microphone arrays,

- 2 circumferential traversing positions for aero/ acoustic probes

- Up to 500 microphone locations

- Fan efficiency measurement by mass flow, pressure, temperature/ torque